© 2022 Wszystkie prawa zastrzeżone. Zaprojektowane przez ZAPIER

Made with ❤ ZAPIER

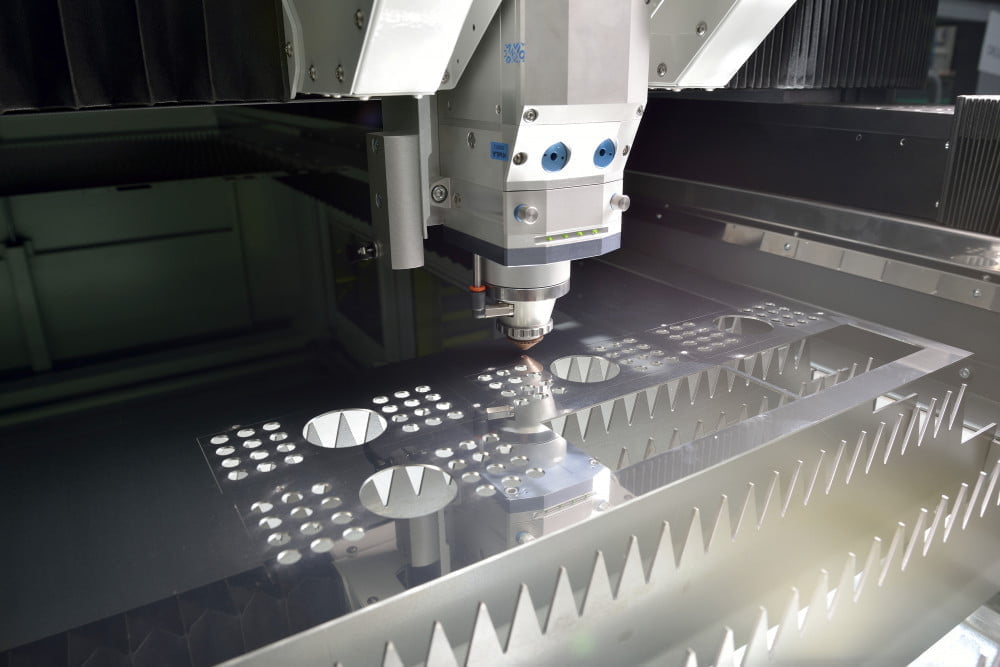

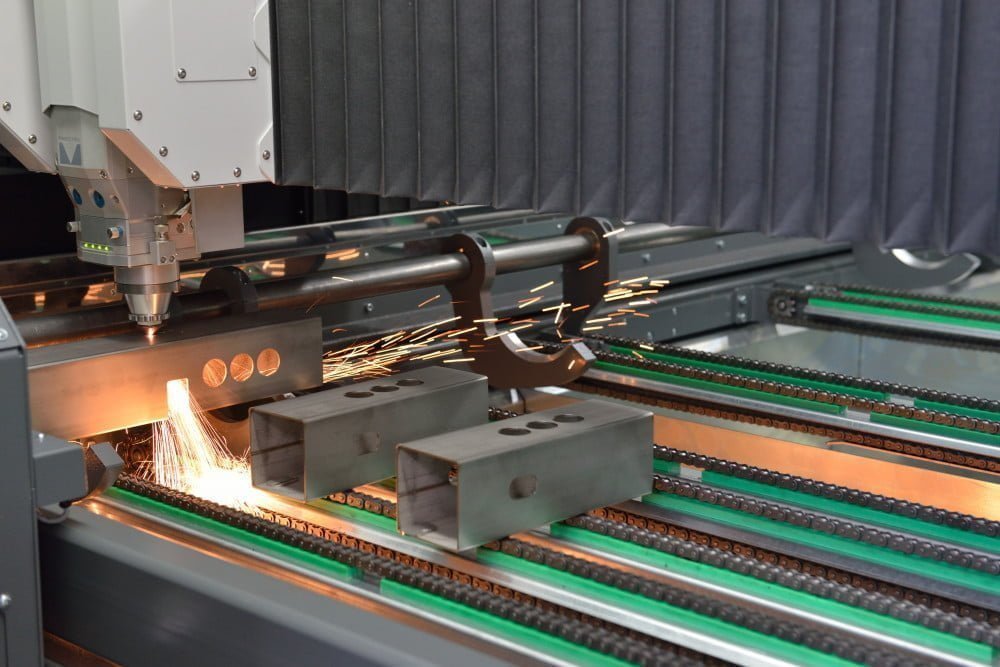

This method is currently the most modern of processing steel or aluminum, as well as other metals and it has an outstanding advantage over traditional processing. Using a laser for cutting guarantees speed, precision and competitive prices. The method we use allows for much faster and more accurate execution of orders, which tranfer to shorter delivery times. And thanks to the high efficiency of the equipment we work on and its innovation, we are able to effectively reduce the amount of unnecessary waste to the minimum. Thus, to perform 100% repeatability in accordance with the received technical documentation. Currently, we provide sheet metal, pipe and profile cutting services using a 6kW KIMLA POWERCUT laser cutter with a 3000×1500mm working table. We also offer cutting in round, square and rectangular profiles, for which, along with the progress of technology, the requirements for them are increasing. Therefore, profiles with complex cutouts and complex shapes are increasingly used, which we are also able to offer.

Our laser can perfectly handle all kinds of sheet metal, whether stainless steel, aluminium or brass. The Kimla PowerCut laser is a state-of-the-art device that enables precise and fast cutting. It burns out complex shapes and creates precise holes, which we can then GRATE.

The laser we use is one of the superfast Fiber lasers. It is an excellent tool that allows precise cutting of profiles and burning of holes of any diameter in stainless steel, aluminium or brass. It is a professional tool that allows you to achieve high-quality results.

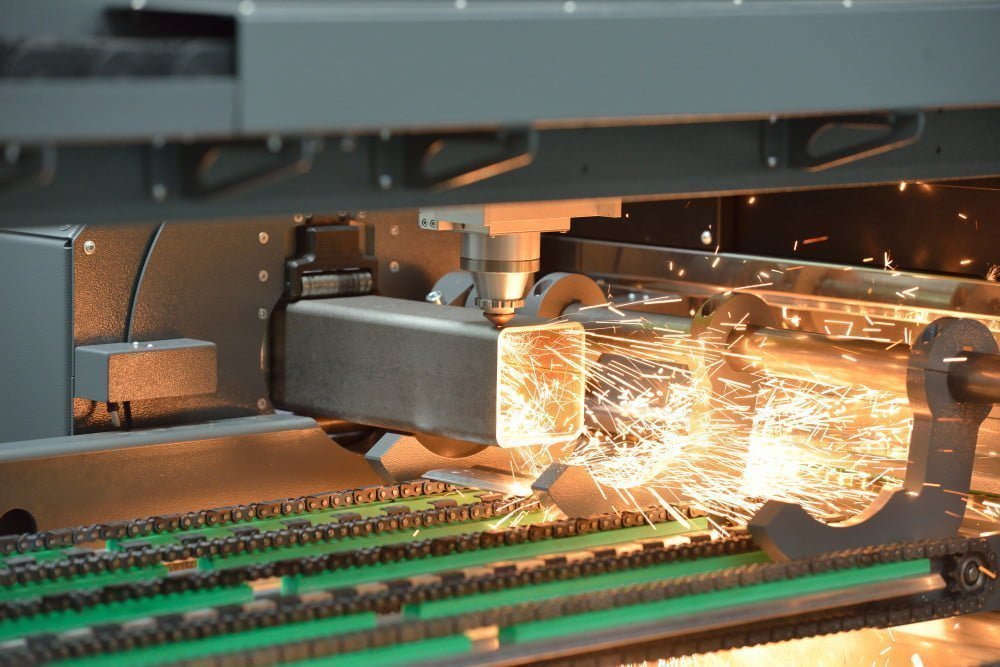

The laser beam is generated by a laser source which is then focused on the material to be cut. The material is then vaporized or burned by the laser beam, leaving a clean and smooth edge. During work, a laser beam is used, which distributes a huge amount of energy on the selected surface. It is worth to point out that the described energy accumulates in a small space. This process allows the most accurate cutting of materials such as stainless steel and more. Appropriate use of laser beams makes this method very effective.

At the outset, it is worth emphasizing that the laser cutting solution we describe is the fastest and most effective method of working on the material, because the cutting speed reaches up to 1m/s, compared to other mechanical solutions available on the market. Precision allows you to obtain smooth edges that do not require any additional work and allow you to make any number of products that will be 100% identical. And which are immediately suitable for further work, e.g. bending. A wide range of processed materials, flexibility and material savings are undoubtedly elements that speak for the choice of laser cutting. It is worth bearing in mind that such a solution is associated with slightly higher costs in the case of a small number of repetitions than in the case of mechanical processing, but in return we get a product of the highest quality, perfectly processed, and, what is worth emphasizing, quickly delivered to the customer, which can sometimes influence on the choice of a client.

Even the most complex contours can be cut with a laser, which is an effective alternative to the technology of saw cutting, drilling or milling. Regardless of the material, the speed and precision of the service, compared to conventional methods of cutting sheet metal or other metal elements, is incomparable, and the unit costs themselves decrease with a greater order potential. An undoubted advantage is the possibility of using one tool, which is a laser, for precise cutting in various types of materials, of various thickness and geometry, and in comparison with other conventional methods. Laser cutting also reduces the number of devices needed and save time to replace components and reduces errors due to human causes.

Laser cutting is otherwise a thermal separation process. The laser beam reaches the material and heats it until it melts. With the force of the blowing of the cutting material, a gap is created from which liquid metal falls off. Laser processing cuts the primary product, e.g. stainless steel according to the selected geometry, while causing separation of the workpiece. The actual cutting process takes place when the laser beam completely penetrates the sheet.

Fiber laser cutting technology allows you to achieve the highest quality with minimal consumption of post-production waste. Many events have caused the laser to take the place of other processing methods in many branches of the industrial sector, where precision and the minimum time is needed to achieve a successful final result are the most important. Its use can be found in:

This method is called the technology of the future mainly due to the extremely precise cuts, speed and lack of deformations. A laser for cutting steel and aluminum is an extraordinary accuracy of details that can be used in many industries. A great advantage of using is also the possibility of creating a 100% repeatability along with obtaining a smooth and clean cutting surface on any material, including stainless steel. According to statistics, thanks to laser processing, it is possible to shorten the production time four times, ensuring full efficiency and complete optimization of work. Reliable and precise lasers allow versatile cutting of details for which error limits are in the range of +/- 0.1mm.

The Kimla Fiber laser that we have is an ecological and environmentally safe laser – its use helps to save as much as 80% of the energy that our company consumes from renewable energy sources. And due to the fact that all our services are provided on the premises of our plant, we are able to ensure the shortest delivery time and deliver the finished product throughout the country.

First of all, we have modern machinery, many years of experience on the market, a qualified team of employees and a wide range of related services. Thanks to this we are able to provide comprehensive services, and our well-located production plant located in Gdynia allows us to provide services by land and sea directly to our customers in the country and abroad. Do not waste your time and drop us your line.

Our company has been on the market since 1991, we provide a wide range of services even for the most demanding customers.

We have many modern specialized machines, thanks to which we create comprehensive services for our clients and partners.

To meet the expectations of our customers, we work on efficient machines that allow for short term processing.

We work in Lean Management standards constantly optimizing our processes, thanks to it we can offer competitive prices.

© 2022 Wszystkie prawa zastrzeżone. Zaprojektowane przez ZAPIER

Made with ❤ ZAPIER